Description

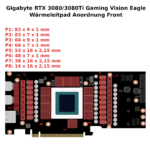

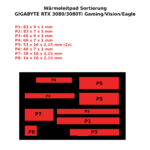

To keep graphics cards functioning properly, the graphics card’s factory thermal pads need to be replaced every now and then. This can be associated with a lot of effort under certain circumstances: In order to achieve sufficient cooling of the various components, it is necessary that all pads have exactly the right dimensions, otherwise this will have a negative effect on the thermal conductivity.

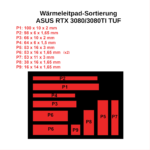

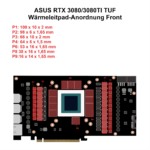

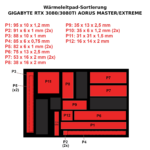

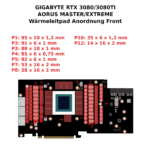

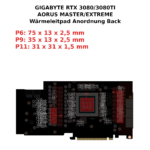

The sets contain all the thermal pads needed for the replacement of the respective graphics card. You save yourself a lot of work because you don’t have to measure and cut the pads all individually.

The thermal pads are pads from our EC360 GOLD series. They present the intermediate variant of high-performance thermal pads, which are on eye-level with premium thermal paste. The pads have an extraordinary thermal conductivity of 14.5 W/mK.

The pads are not adhesive, but stick a little, so they can be easily positioned. It is the perfect solution for heat-transfer in adverse surface conditions when the use of thermal paste is unsuitable. Handling is particularly safe, as the pads are electrically isolating and there is no risk of short-circuiting.

Note: There are sometimes different versions of graphics cards from the manufacturer because the circuit board is sometimes slightly adapted over the years. Therefore, there may be slight differences in some thermal pads.

In the vast majority of cases, our graphics card sets are compatible. In cases where it does not fit, please write us a message.

Specs

Types and Configurations

| Models |

|---|

| ASUS RTX 3080/3080TI STRIX |

| GIGABYTE RTX 3080 / 3080 TI Gaming/Vision/Eagle |

| ASUS RTX 3080/3080TI TUF |

| GIGABYTE RTX 3080 / 3080 TI AORUS MASTER / XTREME |

Technical properties

| Properties | Unit | Value | Test method |

|---|---|---|---|

| Color | - | black | Visual |

| Thermal Conductivity (X-Y) | W/mk | 1500.0 | ASTM D 5470 |

| Thermal Conductivity (Z) | W/mk | 25.0 | ASTM D 5470 |

| Thermal Resistance | °C-in2/W | 0.45 | ASTM D5470 |

| Specific Gravity | g / cm³ | 2.1 | ASTM D 792 |

| Hardness | Shore A | 85 | ASTM D 2240 |

| Tensile Strength | psi | 650 | ASTM D 412 |

| Conductivity (Electrolytic) | s/cm | 19000 | ASTM D 257 |

| Usable Temperatures | °C | -40 - 140 | - |

| Flame Rating | - | V0 | UL 94 |